Technology is evolving. It would only make sense for technology to aid in virtually all aspects of life. This includes businesses. We are seeing the integration of technology in businesses, moving them forward and creating a more efficient process than we’ve ever seen before.

With the use of AI (Artificial Intelligence), manufacturing is just one of the fields that technology is used to advance. There are some that see this as a disadvantage to human workers, but the fact is that AI can help everyone in the manufacturing business move forward.

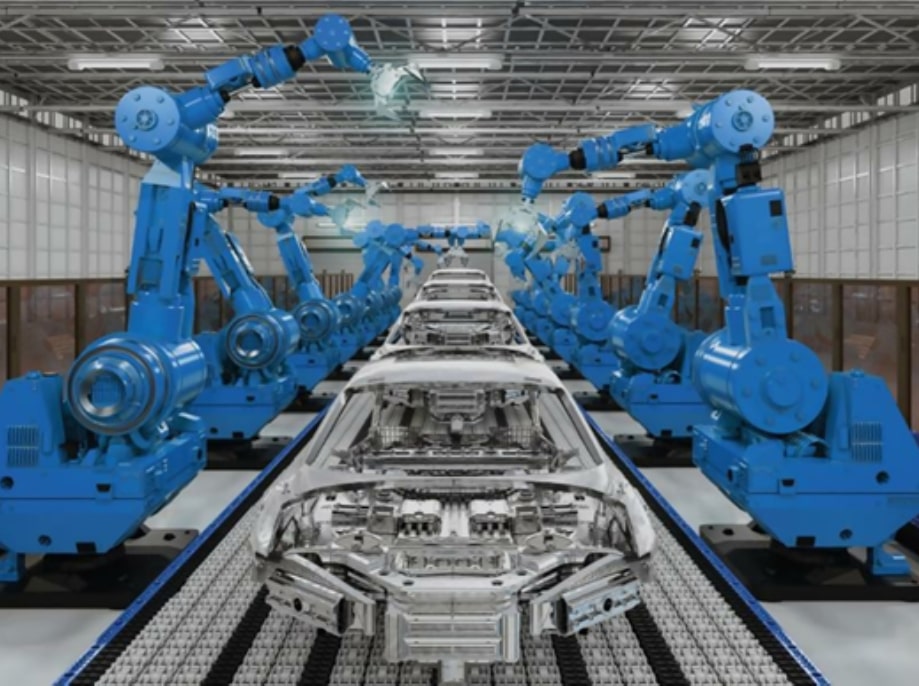

Manufacturing has always been the backbone of businesses in America and around the world. Whereas we began in factories with human labor that could be dangerous at times, we have much of this process automated by technology. According to Manufacturing Global, there was an estimate of 1.3mn robots on production lines at the end of 2018 globally.

Think about how efficient things will be with the use of AI and how efficient production has already been with its help. Here are the areas that AI helps businesses improve on:

Efficiency

When you want a job done, you want it done well and on time. Integrating robots and AI into your business will ensure that deadlines are always met. Not only that, but it will make sure that each item is just the same as the ones before it and the ones after it.

Productivity

With AI, you will be able to increase your productivity. A process on your production line will be able to be increased and achieved at a faster rate, therefore you can have business moving faster than it would have been before. This means more products are shipped out and there are more earnings to be made with technology on your side.

Error Rates

We’re only human and therefore, we make errors. While this was factored into business, as usual, AI helps reduce the error rate substantially. Any person could then in turn even integrated technology into their own job position to help reduce the rate of errors that they may have made before bringing technology to the table.

The thing about it, a human can only do so much and while the tried and true way of working a production line was with humans working the lines, a robot is designed and programmed to not fail. This may seem like jobs will be taken away from people. While this certainly means that they use for a person to actually work the line will be out, you will need people to monitor the robots. As well as those who can be there for repairs and system updates.

Self Repair

Another way that AI is helping with already existing machinery is its ability to adapt and learn. Sometimes the problem is having outdated machinery or a computer system, but technology is evolving to the point where it learns on its own. So that you don’t have to worry about the costly repairs that it would have taken to constantly update the machinery.

It’s according to a McKinney report that maintenance costs were reduced by 10% to 40% by the implementation of AI. Efficiency increased and the number of errors made decreased. These are percentages that you want to see when you are taking into account how to improve your business. It starts on the production line and it starts with introducing present-day technology to your manufacturing.

The manufacturing industry is something that has really improved our society. Since the Industrial Revolution, we’ve seen what the implementation of machinery and technology can do. This was decades ago and now, the advancement of what our computers can do is even more vast than we could have ever imagined.

Introducing technology into the workforce may be scary for some, but it is almost a necessary change that can help. If you are punching the numbers and trying to figure out what would help your business move forward, it is time to really sit down and look into AI for your manufacturing business.